How Do You Repair A Socket Wrench

Ratchet Rebuild

Updated: Jun. xxx, 2022

Easy set up for a broken ratchet

Don't throw away a proficient ratchet wrench that suddenly jams or won't change directions. Have it apart and grease information technology, and if that doesn't work, rebuild it with an inexpensive kit.

You might also like: TBD

Finding and fixing the trouble

Got a ratchet that's jammed, rusted or won't switch directions? Don't toss information technology, rebuild it. In nigh cases, you can slap yours dorsum into shape with just a good cleaning and new grease. Merely if you've broken a bound or a pawl, y'all'll need to buy a rebuilding kit. A rebuild kit for most major brands costs about $10. To detect one for yours, just enter the ratchet brand and model number in a search engine, or attempt ebay.com.

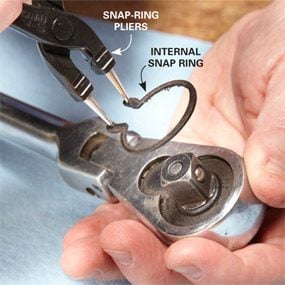

Before you buy a kit, detach the ratchet to assess its status. Apply a combination snap band pliers (one make is Tekton No. 3578; bachelor through our amalgamation with amazon.com to remove the internal or external snap ring from the ratchet head (Photo 1). Or use a pocket-size flat-blade screwdriver to remove a spiral snap band (Photo 2). If your ratchet doesn't employ snap rings, it'll come autonomously with either a hex wrench or a screwdriver.

Throw a towel over the ratchet (to capture flight springs) and slide the entire ratchet assembly out of the caput. Clean the parts with brake cleaner and an old toothbrush. Remove any rust with a rust removal chemical. If the spring ends are intact and the pawl teeth are sharp, you lot tin can reuse them. If not, purchase a rebuild kit. Then apply a low-cal blanket of wheel bearing grease to all the parts. Don't use engine oil; it'll just drip out. And don't pack the caput with grease—that'll prevent the pawl from reversing. Then reassemble (Photo 3).

Required Tools for this Projection

Take the necessary tools for this DIY project lined up before you start—you'll relieve time and frustration.

You lot'll also need a small-scale flat-blade screwdriver and snap-ring pliers.

Required Materials for this Project

Avert terminal-infinitesimal shopping trips by having all your materials ready ahead of fourth dimension. Here's a list.

Originally Published: June 20, 2022

How Do You Repair A Socket Wrench,

Source: https://www.familyhandyman.com/project/ratchet-rebuild/

Posted by: castellanoslittevers.blogspot.com

0 Response to "How Do You Repair A Socket Wrench"

Post a Comment